Ask the Experts

The Experts

Craig H. Benson, PHD, PE, DGE, BCEE, NAE

Craig H. Benson is an international authority on landfills and waste containment. His expertise includes municipal solid waste, hazardous waste, coal combustion residuals, mining and mineral processing wastes, and low-level radioactive waste. He has conducted applied research and consulting on a range of landfill issues for more than three decades. Benson served as Dean of Engineering at the University of Virginia and in various leadership roles at the University of Wisconsin-Madison before entering emeritus status. Benson is a Professional Engineer, Past-President of the ASCE Geo-Institute, and a member of the National Academy of Engineering.

Craig H. Benson is an international authority on landfills and waste containment. His expertise includes municipal solid waste, hazardous waste, coal combustion residuals, mining and mineral processing wastes, and low-level radioactive waste. He has conducted applied research and consulting on a range of landfill issues for more than three decades. Benson served as Dean of Engineering at the University of Virginia and in various leadership roles at the University of Wisconsin-Madison before entering emeritus status. Benson is a Professional Engineer, Past-President of the ASCE Geo-Institute, and a member of the National Academy of Engineering.

Robert B. Gardner, PE, BCEE

Bob holds B.S. and M.E. degrees in civil engineering from the University of Virginia. He is a Senior Vice President of SCS Engineers and has been with the firm since 1980. He serves on the firm’s Board of Directors, and oversees SCS’s nation-wide solid waste management practice. His expertise is in solid waste management and environmental engineering. He provides consulting and engineering services to municipal and private clients throughout the United States and abroad. Bob is involved with the Environmental Research and Education Foundation Research Council. He is a past Director of Solid Waste Association of North Americas Landfill Management Division, and is a member of SWANA’s Applied Research Foundation.

Bob holds B.S. and M.E. degrees in civil engineering from the University of Virginia. He is a Senior Vice President of SCS Engineers and has been with the firm since 1980. He serves on the firm’s Board of Directors, and oversees SCS’s nation-wide solid waste management practice. His expertise is in solid waste management and environmental engineering. He provides consulting and engineering services to municipal and private clients throughout the United States and abroad. Bob is involved with the Environmental Research and Education Foundation Research Council. He is a past Director of Solid Waste Association of North Americas Landfill Management Division, and is a member of SWANA’s Applied Research Foundation.

The Questions

1. I keep hearing and reading about work to construct a “sidewall odor mitigation system.” What exactly is that and what is the project’s goal?

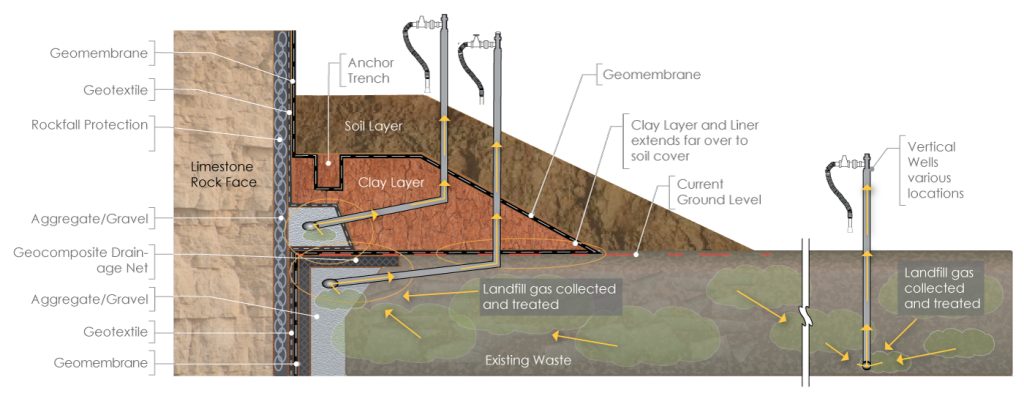

The sidewall odor mitigation system (SOMS) is being constructed around the perimeter of the landfill. The purpose of the system is to capture landfill gas inside the sidewall liner and remove any landfill gas that has found its way between the liner system and the quarry rock sidewall. A conceptual drawing of the cross section of the sidewall odor mitigation system is shown below.

Schematic of sidewall odor mitigation system used to remove landfill gas approaching the sidewall and to prevent releases of gas that has reached the sidewall.

The City is already pulling landfill gas from the initial segment of the system and it is working effectively. The collected gas is mixed with gas being collected from the existing gas collection system in the landfill, and then transferred to the on-site, gas-to-energy plant where the gas is used to produce renewable electricity. When the gas-to energy plant is not in operation, landfill gas is sent to the flare and burned off. As construction took place, the SOMS has had a significant impact in the reduction of odors emanating from the landfill.

Clay layer being placed to prevent odors escaping along the sidewall.

2. The landfill stopped taking waste in September 2022, which is now over eight months ago. What work has been done to remediate odor issues at the landfill?

The following work has either been completed or is well underway by the City to remediate odors from the landfill:

- The City placed 12” of interim cover soil across the entire landfill surface in October 2022. The interim cover soil covers the waste and reduces surface emissions.

- Construction of the SOMS began at the end of 2022, with landfill gas being collected from the initial segment of the system. The SOMS will be fully operational and under vacuum by June 14, 2023.

- SCS Engineers has designed an expanded landfill gas collection system, which includes adding new deep wells; enhanced and expanded landfill gas collection piping; and pumping systems to remove liquids that accumulate in the landfill. SCS also designed and installed a series of polyethylene well skirts that ensure landfill gas and odors cannot escape along the gas well casings. The landfill gas system upgrades are under construction with 18 perimeter wells constructed and under vacuum and 14 of 16 dual-phase extraction wells constructed as of June 5, 2023.

New gas well attached to gas extraction system

3. What is the goal of the gas well expansion project that is being installed?

The goal of the gas well expansion project is to enhance gas collection throughout the landfill. New gas wells are being installed around the perimeter of the waste near the quarry sidewalls as well as in the interior of the landfill. These new wells will increase the efficiency of gas collection at the site, which will reduce odors, and draw gas away from the sidewalls. In addition, deep wells are being installed with pumps to remove liquids that accumulate in the wells. This improves the efficiency of gas collection while removing liquids and heat from the landfill. Finally, new lines are being installed to improve the delivery of collected gases with multiple pathways throughout the system. The new header lines will enhance the reliability of the gas collection system and simplify maintenance.

During installation of the new gas wells, a vacuum box is placed over the surface where the drill enters the waste. This box extracts gases continuously, including odors emitted from the waste as the drill proceeds downward. Gases removed by the vacuum box are treated by the gas collection and control system (GCCS).

Utilization of vacuum box during installation of new gas wells.

4. What other measures are being implemented to address odor and environmental issues at the landfill?

The remedial plan for the site includes placement of interim cover, installation of the SOMS, construction of an enhanced landfill gas collection system, monitoring of the landfill temperatures, removal of liquids from the landfill gas wells, monitoring of landfill settlement, installation of an ethylene vinyl alcohol (EVOH) geomembrane cover, and implementation of a stormwater management system. The EVOH geomembrane cover will reduce infiltration of precipitation into the waste and provide a barrier to odor emissions from the landfill surface. The EVOH geomembrane cover will be installed after the landfill gas system and other surface features are completed. A final cover system will be installed sometime in the future after the landfill has stabilized.

5. What trends are being observed in the temperature monitoring that is being conducted at the landfill?

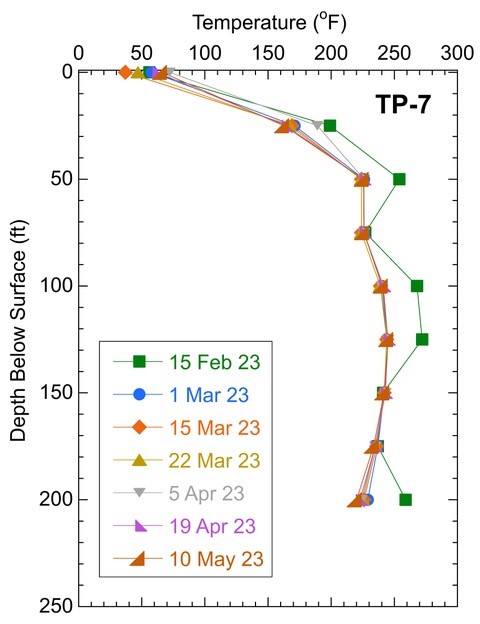

Monitoring strings, installed in the waste since December 31, 2022, record temperature via a remote system. Each string is comprised of a bundle of thermocouples installed in a stainless-steel casing. The thermocouples measure temperature at 25-foot intervals of depth, with some strings reaching as deep as 200 ft below the surface. The results of these temperature recordings are included in monthly compliance reports to VA DEQ which are also posted monthly on the bristolvalandfill.org website.

Waste temperatures measured with these strings have produced temperature profiles similar to those recorded at other elevated temperature landfills in the United States. An example from one string is shown in the graph below. The temperatures increase with depth, reaching a peak at 150-175 feet below the surface, and then diminish with greater depth. The temperature profiles have been very stable, with no significant increasing or decreasing temperature trends. Similar temperature profiles have been observed at other elevated temperature landfills.

Example of waste temperatures recorded with thermocouple strings in the waste. The temperatures are stable.